In the demanding and regulated world of the automotive industry, every detail counts. The interior of a vehicle is not just a space for transportation; it is a real living space that can sometimes become cluttered.

Objects rolling around under the seats, groceries spilling out at the first turn, or equipment shifting around in the trunk of the car… These situations are not only annoying, they are a potential source of distraction for the driver and, by extension, a significant safety risk.

In the event of emergency braking or a collision, basic physics comes into play. An unsecured object becomes a projectile, whose kinetic energy can cause serious damage.

This is where storage and restraint nets come in. They are not just an accessory, but a safety component, designed to ensure that every item inside the vehicle remains securely in place, protecting both the occupants and the vehicle itself.

Eurosandow designed its first car net in 1995 for the Citroën Saxo model of the time. Since then, our expertise has continued to evolve, keeping pace with innovations in the automotive market. Our know-how is not limited to manufacturing; it begins with an understanding of industrial constraints, safety standards, and end-customer expectations.

We work closely with design offices, equipment manufacturers, and car manufacturers to develop storage solutions suitable for all types of vehicles.

What are the different types of nets inside a vehicle?

The interior of a car or utility truck consists of a set of areas with distinct functions, each requiring a tailored approach. Our catalog of car nets is designed to cover all of these needs, from securing heavy loads to organizing and storing small personal items.

Rear seat pocket net

This is one of the most popular storage solutions. Attached to the back of the driver’s or passenger’s seat, the pocket net allows rear passengers to easily store everyday personal items such as magazines, bottles, tablets, first aid kits, or small toys.

Easy to access, this net keeps essential items within reach without cluttering up legroom. It is a universal solution that fits perfectly in any type of vehicle: city cars, SUVs, camper vans, motorhomes, or utility truck cabins.

Empty pocket net

Designed to be attached to the interior door panels, center consoles, or side panels, it transforms every corner of the car into a smart storage area.

It is the ideal solution for safely storing small items (smartphones, wallets).

This solution saves space by making use of vertical surfaces and walls that are often unused. Its tight mesh prevents small items from falling out and getting lost, protecting them from shocks and falls while driving.

Envelope net

The wrap-around net (also known as a vertical net or hammock net) is the most ergonomic solution for securing items in your cargo area. Strategically attached to the trunk opening or against the back of the rear seats, it forms an elastic “pocket” that suspends and stabilizes your items.

It divides the trunk without reducing its volume, creating a storage area that is accessible in one easy step when the tailgate is opened. Equipped with hooks, this net can be installed and removed in seconds using the original anchor points.

Footwell net

This elastic net is positioned on the floor of the car, often anchored between two rear or front seats, to make use of the space known as the “footwell.” It allows you to store small items while keeping them out of sight but within reach.

Trunk floor net

The trunk floor net, or floor net, is the most effective securing solution for stabilizing your heavy loads. Unlike vertical storage solutions, it works by applying horizontal pressure: stretched between the car’s four anchor points, it “flattens” your items to the floor.

It protects your personal belongings while preventing repeated impacts against the plastic walls or carpet, limiting premature wear and tear on the interior of your trunk.

Its elastic structure effectively holds bulky items such as suitcases in place.

The luggage net or divider net

Large vertical net, acting as a physical barrier between the trunk (especially in SUVs and loaded station wagons) and the passenger compartment of the car. When loaded up to the roof, it holds luggage, packages, or sports equipment that could become dangerous in the event of an impact.

Ideal for dog owners, it creates a safe space for your pet in the trunk, preventing it from jumping onto the passenger seats and ensuring a peaceful journey.

What criteria and characteristics should be taken into account?

To ensure the safety, durability, and seamless integration of an auto net into a vehicle, several technical criteria must be taken into account.

Tensile strength (load): this is the number one safety criterion. The maximum load that the net must be able to withstand without tearing or deforming must be assessed.

Density and mesh: the size of the mesh must be adapted to its function. A very fine mesh is ideal for storage nets. It holds small items (keys, pens, smartphones) without them falling through. A wider mesh that is both sturdy and elastic is preferable for holding heavy loads (trunk nets).

The durability of the attachment points: a net is only as strong as its anchor points. It is vital to consider the quality of the hooks, the reinforced seams at the ends, and how the systems are integrated into the cabin.

Abrasion resistance: in a car trunk, the net is constantly subjected to friction from objects. We select synthetic threads (polyester or high-density polypropylene) with high abrasion resistance. This prevents premature wear of the fibers and ensures that the net retains its properties over time.

Aesthetic integration: the auto net must blend in discreetly. The choice of color, finish, and texture must match the color scheme of the car interior (harmony). We offer a wide range of colors and finishes to perfectly match the upholstery and plastics of the passenger compartment, ensuring discreet and elegant integration behind each seat.

Which materials should you choose?

The choice of materials used for an auto net depends on its mechanical, aesthetic, and environmental constraints. Among the most commonly used are:

Polypropylene: lightweight, resistant to moisture and chemicals, it is ideal for the automotive industry.

Polyester: highly robust, it offers excellent durability over time, even under heavy mechanical stress.

Cotton: rarer and more specific, cotton is used for decorative applications or luxury vehicle interiors, offering a natural textile look and unparalleled softness to the touch.

Polyamide (Nylon): known for its high elasticity and abrasion resistance, it is well suited to products subject to frequent deformation.

Natural latex: used as the core thread in elastic cables, it provides optimal elasticity and good tension support for the net.

Each material has specific advantages that are taken into account depending on the technical, aesthetic, and economic requirements of the project.

What kind of frame?

The integration of a storage net on a seat or in the passenger compartment depends heavily on the frame on which it is mounted. This frame structures the net, influences its strength and performance in use, and contributes to the final aesthetic appearance.

The choice of this structure varies depending on the product’s destination (back of the seat, side walls, or loading areas) and the requirements of the specifications.

The plastic-coated metal frame is a robust and proven solution, widely used for storage nets behind front car seats.

Covered with a plastic coating, it offers excellent resistance to impact, wear, and corrosion, while ensuring a neat finish.

In the same vein, there are also plastic-coated steel frames, which offer enhanced strength.

Depending on the requirements for lightness or flexibility, the frame can be made from various engineering plastics such as polyethylene, POM, polypropylene, or polyamide (which can be reinforced with glass fibers for greater rigidity).

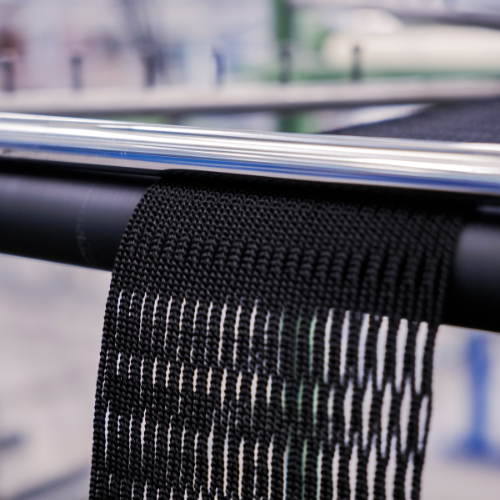

For a more discreet integration and minimal weight, you can opt for a woven strap contour. This flexible solution adapts to curved surfaces and allows for simplified attachment, often via hooks or direct stitching.

What types of fasteners?

Hooks: Available in metal or injection-molded plastic, they allow you to hang the net in an instant.

Carabiners and elastic loops: These systems ensure optimal tensioning of the mesh, ideal for storage that adapts to the volume of the items being transported. These elements facilitate securing the device to the back of the seat or to the anchor points on the frame.

Frame integration:

For products with a rigid frame, fastening clips are generally used. These small plastic parts clamp onto the frame to secure it perfectly to the car seat structure. They ensure the visual and mechanical stability that is essential for perceived quality.

Boutterollage

In mass production for equipment manufacturers, the boutterollage technique is the gold standard. This thermal process involves locally heating the plastic to create a fusion between the net support and the seat structure.

Unlike simple hooks, tufting ensures permanent hold. The net becomes an integral part of the seat, offering exceptional resistance to tearing and unbeatable durability, even after several years of intensive use.

What color options are available?

While black remains the most commonly used color for seat nets due to its discretion and versatility, it is entirely possible to customize the color of the product to suit the aesthetic requirements of your project.

At Eurosandow, we design custom nets based on your specifications. Thanks to our expertise in weaving and knitting, we can offer plain or multicolored nets, playing with the threads or textile straps used.

A striking example: we developed a net made from orange straps for the very first Renault Captur model. This bold color choice, integrated directly into the vehicle’s design, perfectly illustrates our ability to adapt our products to the aesthetic requirements of manufacturers and equipment suppliers.

Mastering the manufacturing process

An automotive net is much more than just a component. These are technical textile solutions whose performance is guaranteed by rigorous industrial expertise. We are committed to providing products that enhance safety while improving the perceived quality of car interiors.

The transformation of the raw materials described above into reliable finished products is governed by an IATF 16949-certified industrial process. Our expertise is evident in the precision of our assembly and the rigor of our controls. Our R&D department supports our customers in the design of custom-made nets. From modeling to prototyping, each element is studied based on specifications to ensure perfect integration and functionality (for example, on the back of a seat) from the design phase onwards.

Automotive nets are generally knitted. With our 12 knitting machines, we are able to quickly produce storage solutions for our customers and meet tight deadlines. Each product undergoes rigorous mechanical testing (break strength, abrasion resistance) and is delivered ready to install with its hook fastening systems. These measures ensure that the final product meets the parameters defined during the design phase.