Straps essential for comfort and safety

In the automotive industry, every detail counts. Seat belts play an essential role in passenger safety and comfort. They provide support, hold the foam in place, and contribute to the ergonomics of the seats. Invisible to the naked eye, but essential for manufacturers and equipment suppliers, they must combine mechanical strength, durability, and reliability.

Eurosandow develops and manufactures a wide range of technical straps for the automotive industry.

Our seat belts are custom-designed to meet the specific requirements of each type of vehicle: city cars, SUVs, light commercial vehicles, heavy goods vehicles, coaches, as well as specialized vehicles such as tractors, cranes, and construction machinery.

Different types of straps

In the automotive industry, straps play a key role in seat design and ergonomics. Depending on their use, they can be rigid or elastic, and are designed to meet specific mechanical requirements.

Seat maneuvering straps

These straps are functional components that enable the chair to be adjusted in various ways: moving, tilting, articulating, or folding. To withstand repeated handling, these straps combine robustness and mechanical strength.

Seat upholstery webbing

Generally woven, they provide support and structure for the seat. These upholstery straps are designed to hold the padding in place and ensure a comfortable seat for drivers and passengers.

Tubular webbing for attaching seat covers to car seats or tunnel band

Also known as “tunnel bands,” tubular straps are used in automotive headliner retraction. Their function is to ensure a perfect fit for covers and trims, for a flawless aesthetic finish.

Their elastic design acts as a built-in tensioner, keeping the cover taut while withstanding the stresses of use.

What materials should be used for car seat belts?

The choice of materials for a strap depends on various parameters. Each fiber has specific characteristics, allowing us to adapt our products to the mechanical, aesthetic, and regulatory requirements of manufacturers.

Here is a list of the materials used by Eurosandow to manufacture its straps:

- Polyethylene and polypropylene: lightweight, economical, and moisture-resistant, they offer good mechanical strength and are used in many applications.

- Polyester: a versatile material with good tensile strength and fatigue resistance. It is widely used in industry.

- Cotton: cotton is a plant fiber that is both supple and soft. Cotton offers a high-quality finish.

- Polyamide (nylon): very strong, combining high mechanical strength and elasticity

- Kevlar: a heat-resistant synthetic para-aramid fiber with a very strong structure. It offers high resistance to stretching and tearing.

- Aramid: This chemical and synthetic fiber, which appeared in the 1960s, offers many advantages: tensile strength, tear resistance, vibration resistance, low density, excellent thermal stability from -70°C to +200°C, infusible and non-combustible, good fatigue resistance, good chemical resistance to fuels and seawater.

- Fiberglass and copper: incorporated into certain specific developments, they provide a particular technical solution (insulation, conductivity, increased resistance).

- Technora: Technora® has excellent resistance to heat (450°) and abrasion.

Custom manufacturing of seat belts

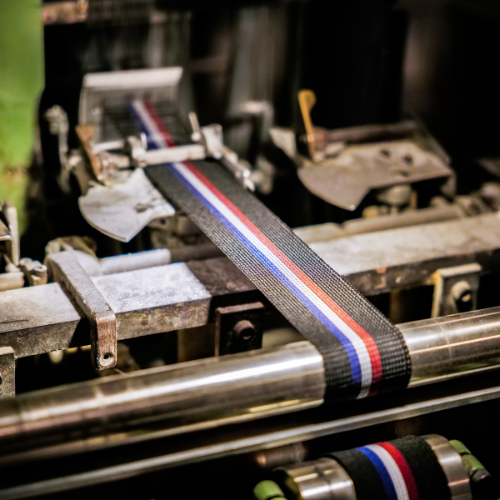

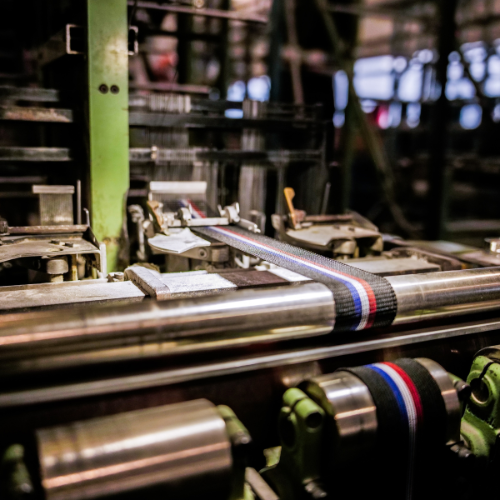

Our straps are designed and manufactured in our workshop in Saint-Étienne, France.

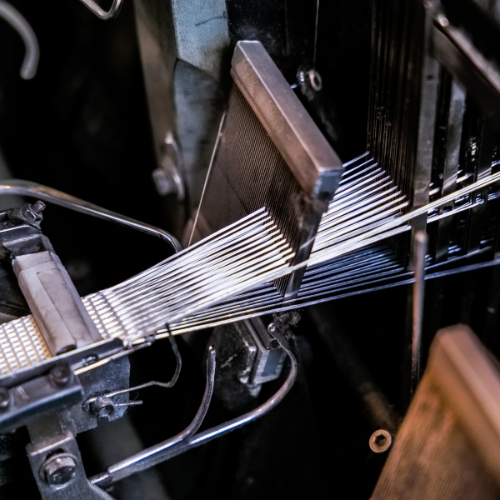

We use sophisticated manufacturing processes, including weaving, braiding, and knitting. These processes enable us to meet all of our customers’ needs and offer solutions tailored to their specifications.

The manufacturing technique will therefore depend on the use case and the desired performance.

Woven straps (flat or tubular) are manufactured by interweaving threads in two perpendicular directions (warp and weft), giving the strap a dense and fairly rigid structure.

Weaving is used, for example, to manufacture seat upholstery straps that hold the seat in place for the automotive industry.

Weaving and knitting, on the other hand, offer greater elasticity and can be used to make straps for holding objects in place.

Depending on the specifications or application of the product, our teams can perform calculations and tests to recommend the most suitable manufacturing process for your project.

To meet the most demanding specifications, our straps, whether elastic or rigid, can undergo heat setting treatment on a specialized line.

This process, carried out on a specialized line, consists of heating the textile at a controlled temperature, with or without the addition of specific additives.

The thermosetting process offers numerous advantages:

- Improved resistance to breakage and elongation,

- Excellent resistance to abrasion and repeated cycles,

- Increased resistance to flammability,

- High-quality finishes.

Custom straps for manufacturers and equipment suppliers

Because every automotive project is unique, Eurosandow develops customized straps tailored to the specific needs of its customers:

- Various widths and thicknesses

- Elastic or non-elastic depending on the application

- Mechanical resistance adapted to the stresses of the seat

- Possibility of specific marking, sewing, or assembly

Ensuring quality products that comply with automotive industry regulations

Quality and compliance are at the heart of our approach. At Eurosandow, every strap undergoes rigorous testing, carried out in accordance with the testing methods used by leading manufacturers (Nissan, Renault, PSA, Toyota, Volvo, Ford, BMW, Volkswagen, Jaguar Land Rover).

- Flammability tests

- Odour tests

- Fogging

- Sweat tests

- Ageing

- Strength and elongation

- Breaking strength

- Fatigue tests

These validations enable us to provide our customers with inspection reports or certificates of compliance according to their needs.

This unwavering commitment to quality, combined with the dedication of each and every one of our employees, earned us IATF certification in 1996 and recognition for QUALITY in both the automotive market and industry.